02/2022 - 12/2022

Project Overview

One of the world leaders of manufacturing and selling fastener products approached rosslight to refine a test concept of the IPEK (Karlsruhe Institute of Technology) and to manufacture a modular test stand. This test stand is designed to measure the torque values of screws when driven into various types of wood.

Solution Provided

The test stand features a modular design, allowing for flexibility and ease of use. Key components include:

- Two Independent Axes for Movement: Precise control over the positioning and movement of the screw drive.

- Adjustable Linear Force and RPM: Ensures accurate simulation of real-world conditions.

- Item Profile Kit, CNC, and 3D Printed Parts: Inhouse manufacturing ensured fast design iterations and a cost effective delivery.

- Mitee Bite Clamping: Fast specimen changes and secure clamping due to eccentric head clamping claws

- Measurement Equipment: Integration of high-quality equipment from NI (National Instruments) and Lorenz.

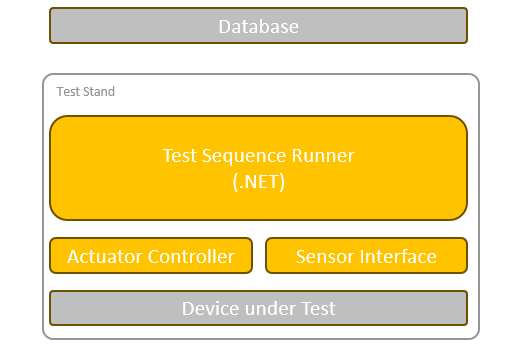

- Automated Test Sequences and Data Analysis: The rosslight software team developed a custom .NET application to automate test sequences and transport data to a seq database for comprehensive analysis and dashboarding.

System Architecture: